In control with Striebig

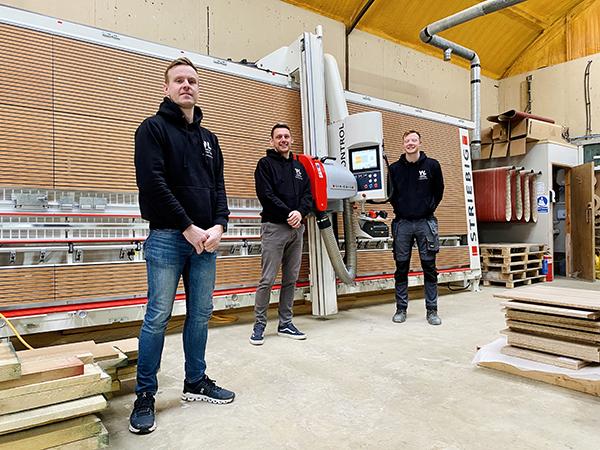

High-end bespoke furniture company, William Loughridge Bespoke Joinery Ltd, turned to the UK’s exclusive Striebig vertical panel saw specialist, TM Machinery and Irish partner, TI Machinery, in a bid to future-proof their business and optimise their cutting processes.

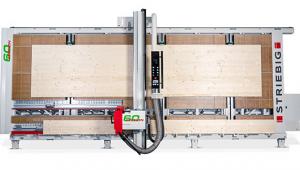

“Automation and digitalisation are game changers in the furniture manufacturing industry,” begins William Loughridge, Managing Director at William Loughridge Bespoke Joinery Ltd. “We knew investment in new technology would benefit our business and, with an over-worked sliding table saw in need of upgrading, we knew it was the right time to optimise our production processes.” The brief was clear: William Loughridge Bespoke Joinery Ltd needed a machine that could cut 18mm chipboard, MDF and veneer panels quickly and precisely while offering a level of automation that would allow them to increase their capacity, reduce material waste and streamline their production. “We presumed a beam saw would be our only option, but due to its size, it would have taken up 50% of our factory floor,” says William. “This wasn’t a practical solution for us; we needed an automated machine that was also space-saving.” The solution was a new Striebig Control vertical panel saw with fully automated cut cycle and a host of new automated features. “We had originally disregarded the idea of a vertical panel saw because we thought they were only suited to rough cuts and small manual cut-to-size operations,” admits William. “It was only after talking to another joiner who was using a Striebig Control and seeing it in action that we knew our misconceptions were wrong. Their Control was a highly accurate piece of kit, which, even after six years of continual use in a busy joinery shop, was still producing precision cuts with an accuracy of 0.1mm and working quickly from detailed cutting lists.”

ExpertCut software

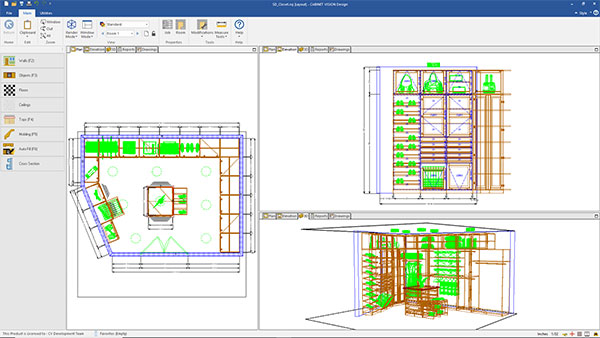

A further demonstration of the newly-released Striebig Control model and advanced ExpertCut panel optimisation software at TM Machinery’s Leicester showroom provided the incentive for the Irish joinery firm to invest in their own Striebig Control a few weeks later. “The fully automated machine partnered with the panel optimisation software topped my wish list,” admits William. “Prior to the Striebig, our only option was to create cutting lists manually and physically set-up the machine to complete the job. It was labour intensive and human error always played its hand.” The beauty of Striebig’s ExpertCut software is that cutting lists are transferred to the workstation remotely, allowing records for cutting optimisation to be imported from standard ERP, CAD systems via CSV-format Excel files before the saw gets to work. William adds: “This has revolutionised the company’s screen-to-machine practices. What’s more, the software analyses each 3D design we create on Hexagon’s Cabinet Vision and breaks down the cabinets into individual machinable components automatically. It calculates the exact number of sheets we need and the most efficient way to cut them. It even works out the wastage on each job and determines which offcuts can be re-used on future projects. We have reduced our waste by more than 80% since integrating Striebig’s software into our production.”

Results that speak for themselves

The introduction of the new vertical panel saw has also simplified the operation on the factory floor. “Not only does the operator no longer need to input cutting lists manually onto the machine, the labelling system speeds up the panel distribution, too. Once cut, we used to write the dimensions of each panel on a panel edge manually and sieve through each panel to find which needed to be edged or taken to our CNC. Now, a label is generated automatically via the saw’s printer for every sized panel. It includes the component’s name, which cabinet it has been cut for, the overall dimensions, if it needs to be edged – and if so, which side – or whether it needs to be sent directly to the CNC. It makes each component easy to identify and saves so much time.”

When it comes to speed, the results speak for themselves: “Previously, a complete kitchen might have taken us three days to cut the necessary components. Now, the same kitchen can be finished in less than a day. It offers us the potential to triple, if not quadruple, our orders, while reducing manual handling. Plus, we’re still able to use our sliding table saw for rough cuts, which helps us avoid a potential back-log of work if the Striebig is in continual use. This has increased our capacity by a further 10%.” With no manual set-up and designed with pneumatic assistance, which sees the saw unit plunge fully automatically into the panel, the operators can focus on the job in hand. William says: “The saw’s touch-screen operating system is user-friendly and the fully-automated cutting cycle makes it fast to use. The automatic head positioning system and panel end detection are particularly useful features, as this means we don’t have to move the stops manually when cutting different lengths. It may sound simple but this standard feature saves us so much time when working on varied cutting lists. It’s also taken the team no time at all to get their heads around the saw’s operating system, as it tells you exactly what to do and how to do it on the display screen.”

Seamless integration

Other advanced standard features include adjustable feed speeds, constant return speed of the saw unit, an operating-hour meter and a digital measuring system on both axes. When it came to integrating the ExpertCut optimisation software into the business, William says the process was seamless: “We knew what we wanted to achieve and we were fully invested in it. We expected some disruption to work flow but the transition period was really smooth. For us, we’re not looking to create a fully-automated production line. Our offer is too bespoke for that and due to the wide range of projects we work on, we will always rely on skilled craftsman to hand-finish each job. But, what the Striebig has done is open our eyes to new ways to make our business run more efficiently. As it stands, the vertical panel saw offers us more design flexibility than ever before and an efficient system for cutting sheet material, plastics and timber. We strongly believe this software will be fundamental to the success of our business going forward and we would recommend it to anyone.”

TM Machinery is the exclusive UK distributor of Striebig. For more information, call 0116 271 7155 or visit www.tmmachinery.co.uk. You can also follow them on Twitter – @TM_Machinery – or search for TM Machinery on LinkedIn.

- Log in or register to post comments