New ‘stefani m’ industrial edgebander from SCM Group

Top-quality machining and productivity on any kind of panel or material and in full sync with the demands of a digital, connected and integrated factory: these are the main advantages of SCM’s new industrial edgebander.

Bolstered by its R&D experience and the market success achieved following the ‘stefani x’ launch back in 2022, SCM has since developed ‘stefani m’ – another new industrial edgebander. This model aims to meet the latest furniture and design trends in terms of flexible production, Industry 4.0 and now, even Industry 5.0.

The new ‘stefani m’ industrial edgebander has everything required to cement its position as a very strong market competitor. Every detail has been designed to offer a solution in line with the industry’s more complex demands: from the machine’s structure to the digital and electronic control systems; from the machining units with power-assisted movement to the latest gluing devices, which allow for an even faster, more efficient glue change.

The result is a highly configurable, customised edgebander, designed to work reliably and provide top-quality machining, both in the stand-alone version and integrated cells. One other important advantage is its ability to achieve maximum quality standards easily and without interruption, even on the most delicate, state-of-the-art materials, thanks to SCM’s new electronic touch technology.

Furthermore, in an attempt to meet the increasingly more widespread demands for flexible, connected and integrated production, ‘stefani m’ is supplied with a ‘Maestro active edge’ control system, meaning it can operate in perfect synergy with the Maestro edgestore manager software, other SCM technologies in addition to MES IT and management systems used within the factory.

Industrial productivity

The new ‘stefani m’ can machine panels at a speed of up to 25m/min and with a minimum 350mm distance between panels. All of this is made possible owing to reliably tried-and-tested units and a new, highly rigid mechanical structure.

Excellent versatility in gluing solutions

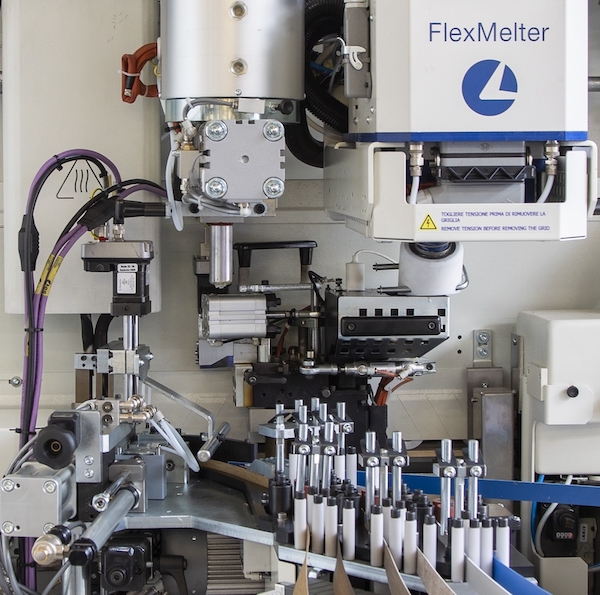

Another of ‘stefani m’s significant new features is the novel gluing unit, which ensures the three key technologies are always ready to hand – PUR glue, EVA glue and Hot Air AirFusion+-, up to six rolls with automatic change of machining edge and edge table height adjustment, which ensures the edge is always correctly positioned on the panel side.

A new, innovative FlexMelter ‘all-in-one’ pre-melting device, which uses EVA and PUR glue in slugs and granules, as well as a fast, waste-free glue change, thanks to the removable container.

High-end electronic units

The ‘stefani m’ electronic units are designed to meet two key market objectives: ease of use even for more complex machinings on delicate, in-vogue materials, thanks to an automatic, flexible set-up and repeatability, quality and accurate production processes, thanks to the electronic touch function.

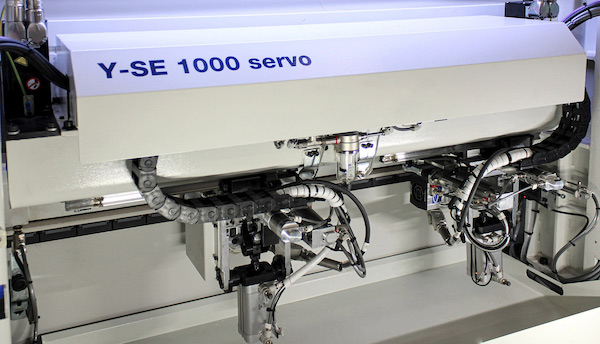

• Y-SE 1000 Servo end trimming unit – for constant precision when cutting, irrespective of the amount and type of panels machined, to optimise machining work even on the most delicate panels, automatically control adjustments and correct any machining errors on the spot.

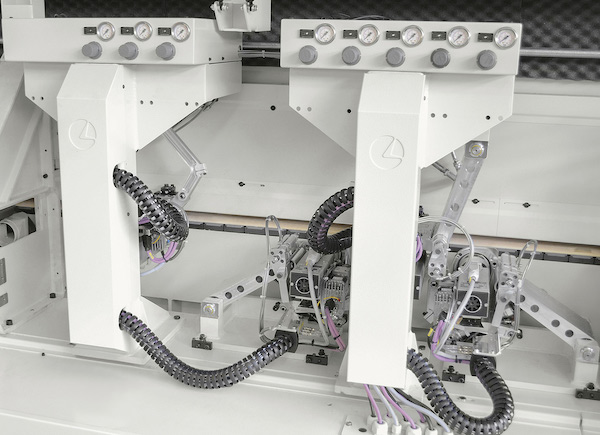

• Round 2 Servo rounding unit – Guarantees top-quality machining on any profile and optimises the processes even on three different edge thicknesses.

For further information, see www.scmgroup.com.

- Log in or register to post comments