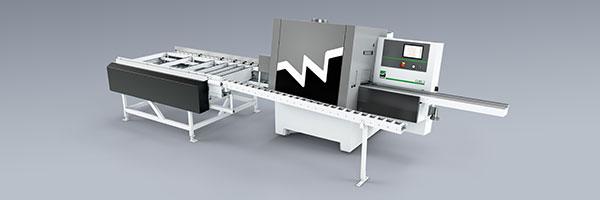

The new Cube 3 automatic planer

To celebrate the Cube’s 10th birthday, leading woodworking machinery manufacturer, Weinig, has launched its brand-new Cube 3. Now in its third generation, the compact four-sided planer, which continues to champion the smaller workshop with its one-man operation, is now available in the UK from as little as £136 per week*.

From small joinery workshops to large timber merchants, the Cube’s success can be attributed to its compact size, simple operation and exceptional level of flexibility. Its iconic ‘plug and play’ concept has set the benchmark when it comes to quick and easy operation – simply set-up, switch on and start planing.

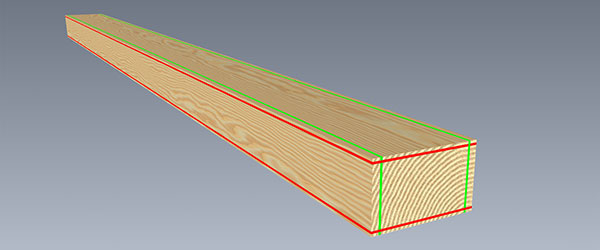

Its standard working height of 8-160mm, working width of 15-260mm and feed speed of 6-12m/min, allows workpieces to be perfectly planed on four sides, all in a single pass.

New features

Not only is the stock price of the Cube 3 lower than its predecessor, with finance available from as little as £136 per week*, the latest model can be specified with an automated stacker and RFC 15 return conveyor. This simplifies handling and ensures easy one-man operation, regardless of workpiece size, while streamlining production flow.

The RFC 15 return feed system’s competitive price means that companies can realistically see a payback on their investment in less than a year but, if you’re not ready to make the leap now, you can retrofit these items at a later date if your Cube 3 is equipped with a ‘prepare package’ at time of build.

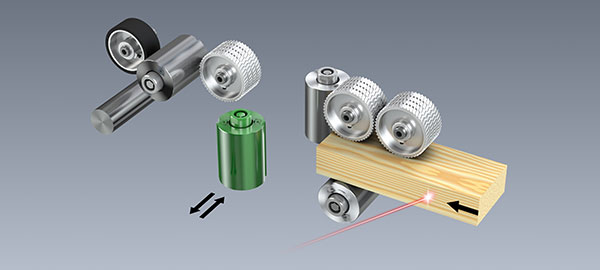

Made from a hardy combination of cast-iron and DUROCEM, the Cube 3 is 10 times faster than conventional machines and has a total connected load of 18kW as standard. It’s also equipped with Weinig EasyLock tools, allowing the quick change of reversible knives inside the machine.

If you’re looking to process workpieces with large chip removal, work at a higher feed speed or plane hardwood, this isn’t a problem for the Cube 3 – simply increase the connected load to 28kW. If you’re wanting to consecutively machine workpieces, a mobile spindle is also available, which makes the automatic planer a robust and cost-effective solution for any business.

Malcolm Cuthbertson, Managing Director of Weinig UK, says: “Weinig UK has sold well over 200 Cubes since it was first launched. For many, the Cube has marked a company’s first step onto the woodworking machinery ladder; for others, it’ll remain at the centre of their production processes, becoming a dependable workhorse when time, labour and space requirements need to be appeased.

“But what truly sets it apart from the rest is its flexibility, productivity, ease of operation and overall safety. That’s why it continues to be a hit with businesses of all sizes, from one-man workshops to non-stop timber merchants providing a quick turnaround of bespoke-size planed material.

"In every case, the Cube provides unrivalled benefits to each and every user. In simple words, the Cube does what it says on the tin and we look forward to sales continuing at high levels now there’s an extended range of options to complement the machine.”

Keen to find out more? Visit https://cube3.weinig.com to explore the new Cube 3 in augmented reality.

*Subject to status.

|

Michael Weinig UK Ltd

5 Blacklands Way, Abingdon Business Park

Abingdon

OX14 1DY

01235 557 600

|

- Log in or register to post comments