Take stock With Striebig

Swiss vertical panel saw manufacturer Striebig showcased its very latest vertical panel saw range and software offering at this year’s Holz-Handwerk. With industry 4.0 and digitalisation very much at the forefront of its presentation, visitors were able to experience the very latest cutting technology alongside a new warehouse management system, Optistock, at the four-day event in Nuremburg.

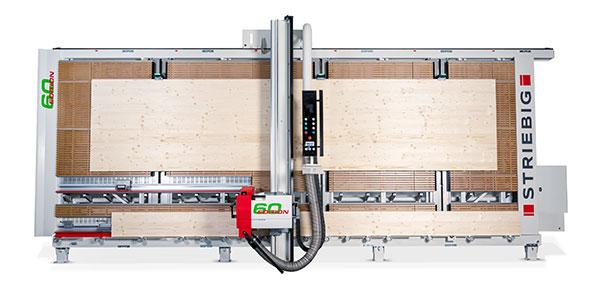

New Edition 60 vertical panel saw

Making its European debut, the new Edition 60 vertical panel saw took centre stage. Designed with single-operator use in mind, the new model, which is exclusively available in the UK through TM Machinery, centres around an integrated panel-lowering device (PAV) comprising two panel-lowering units, which that position each panel automatically. This process eliminates the need to rotate the sheet by hand during the cutting process, thus reducing handling. It’s suitable for use with panels up to 3,000 x 2,159mm and weighing up to 160kg. A third lifter can also be added for cutting large format panels up to 5,000 x 2,150mm, which weigh up to 240kg. The new PAV system is also quick, offering an impressive feed rate of 5m/min under load and 10m/min without load.

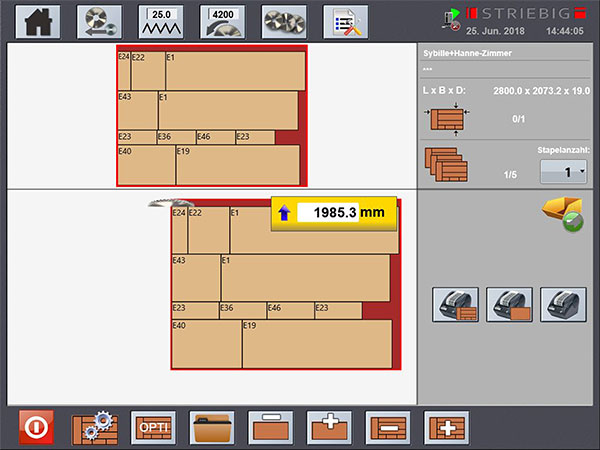

To demonstrate how simple it can be to integrate a Striebig vertical panel saw into your operational data flow, visitors were also given an opportunity to see Striebig’s latest optimisation software on its Compact and 4D models. ExpertCut allows you to take on parts lists from conventional CAD or ERP systems and optimise them directly at your office workstation. You can also use the program to process and manage orders, materials and parts lists quickly and easily.

New Optistock warehouse management module

Striebig’s brand new Optistock warehouse management module, launched at Holz-Handwerk and part of the newly-extended ExpertCut system, is designed to help you manage your external remnant stock. During optimisation, remnants can be allocated to stock and recalled for processing when required. Optistock then adjusts the library of remnants, adding, labelling and numbering any new offcuts as they're created before allocating space in the stock. It's possible to book remnants out manually but Striebig’s Operator Station software, which works with a Windows-based PC, provides a simple graphic representation of remnants, making them easier to manage.

Matt Pearce, Managing Director of TM Machinery, adds: “Striebig is focused on creating and developing market-leading cutting solutions for the woodworking industry. It’s been a core part of the businesses for 60 years and the company continues to push ahead with new, ground-breaking cutting technology with all the hallmarks of a Swiss manufacturer. The new innovations on show at Holz-Handwerk are a great example of what’s to come from the world’s leading vertical panel saw specialist.”

For more information on TM Machinery, visit www.tmmachinery.co.uk.

- Log in or register to post comments