The K-SYSTEM

You can rely on KOCH to answer all your needs with expertise, precision and passion. Partnering with KOCH offers you the full range of possibilities, where transparency and consistency are guaranteed. From their clearly structured range of products, users are provided with the perfect solution to match individual requirements.

Whether gearing up for a profitable launch, optimising production to increase flexibility or configuring a unique system for maximum performance – no matter what you decide, each option is designed with core competencies of the industry‘s leader, resulting in top quality. This is known as the K-SYSTEM.

At its manufacturing facilities in Germany, KOCH produces cutting-edge technology for wood processing. Their product lines, consulting expertise and services, are available around the world at any time through an extensive network of branch offices and in the UK via R&J Machinery Ltd.

Solutions for edge processing

KOCH offers a complete range of edgebanding and hot-foiling machines, from top-quality basic equipment for market newcomers through to fully automated machining centres for large-scale production. Their product lines – base, pro and select – are the basis for an ideal system design. With optional equipment enhancements, each high-performance machine can be seamlessly adapted to suit your specific needs.

* Superior-quality components throughout the range ensures consistently outstanding precision in all aspects of edge processing;

* Production of a wide variety of workpieces – whether profiled, shaped or special parts;

* Complete workpiece processing through enhanced equipment for shaping, drilling, gluing and dowel insertion;

* Manual feed or through-feed;

* Application of a wide variety of edge materials, from paper, ABS and PVC, through to melamine and wooden edges with a minimum thickness of 0.15mm;

* All standard glues, including EVA, PUR and PO.

Solutions for frame processing

From just-in-time manufacturing to high volume production, Shaker, Mitre or French Cut - Koch has the solution for you. High flexibility, wide variety, with low production costs and a high degree of simultaneous machinery utilisation are of particular importance in the component and cabinet industry. KOCH offers concepts for component production, utilising the machines for several types of doors.

Solutions for sawing & drilling

The FLEX series is particularly suited to the fast and flexible production of smaller batches of framed doors. Like all KOCH products, these powerful sawing and drilling machines are characterised by short set-up times and user friendly operation, and their solid construction and engineering ensure high-precision results.

Solutions for drilling & dowel insertion

Well-engineered technology, convincing performance parameters and easy handling characterise the SPRINT series, which guarantees fast and cost-efficient solutions for the production of small- and medium-sized batches, in renowned KOCH quality. Depending on the product line – base, pro or select – along with additional equipment enhancement options, the machines in the SPRINT series can be ideally adapted to suit your production needs.

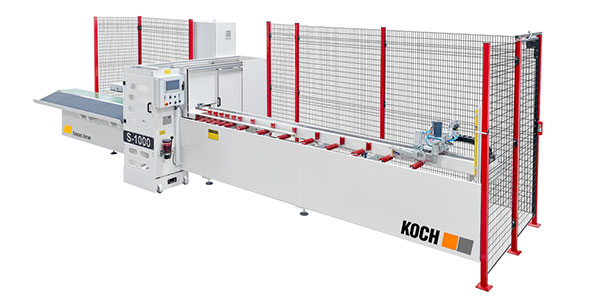

Solutions for sawing, drilling & dowel insertion – double-sided through-feed processing

The sturdy construction of equipment in the BD/SBD series forms the foundation for high-precision processing and consistent reproducible accuracy. Thanks to their modular design, the stations for multiple operations – from sawing and shaping through to drilling and/or dowel insertion – can be seamlessly combined in one continuous, double-sided process. Reliable performance, short set-up times and absolute safety are the hallmarks of this system design.

For further information on the K-SYSTEM, contact R&J Machinery Ltd on 01455 840 224, email [email protected] or visit the website: www.rjmachinery.co.uk.

R&J Machinery's showroom is located on Dodwells Industrial Estate, Hinckley, Leicestershire, LE10 3BY.

YouTube video links

Endmaster K

Peanut insertion

Uniflex

Sprint base line

- Log in or register to post comments