SCM's grand opening of new Technology Center: 28–30 September 2023

From 28–30 September, SCM will hold a grand opening of its new Technology Center in Rimini, Italy.

This is an opportunity to discover how SCM’s latest technological and digital innovations can assist the customer in developing their business. These include the innovative automated Cargo system for CNC machining centres; the new Maestro Lab software and advisory services, made possible by Maestro Connect, that facilitate a new standard in client relations.

New Technology Center

SCM continues to confirm its stance as one of the main industry leaders, which is demonstrated by year-on-year growth and constant new innovations. One such example is investment in its Italy-based industrial sites to increase production capacity and further enhance customer relations. The new Technology Center was created as part of an expansion and modernisation programme at the company's Rimini headquarters, which is due to be officially unveiled from 28–30 September, and aimed at companies and stakeholders from the entire woodworking industry on a global scale.

This 4,000sq.m space is the new digital home of woodworking innovation: every detail has been designed to offer the widest range of technologies and services as well as providing integrated, connected, flexible, more sustainable and optimised processes at each stage of secondary wood processing.

The event will present an opportunity for visitors to discover the latest solutions developed by the Group; these combine strong technological skill for the production of solutions for furniture, doors and windows, timber construction and artisan joinery, with the development of software and services to accompany the client at each stage of the production process.

CNC machining centres range

New machinery on show will include those in the CNC machining centres range, which will form the basis of a dedicated training event. Also, Cargo – an innovative automatic system for loading and unloading doors and panels – and Maestro lab – the new CAD-CAM programming software – will also be demonstrated.

Cargo will be integrated with the morbidelli m200 pods&rails machining centre – a fully automated cell that requires no operator supervision – which is unique in the market due to its ability to continuously load and unload pieces in masked time, while the machine performs drilling and routing operations. This exclusive solution allows for maximum efficiency by avoiding manual work phases and associated costs and downtime, in addition to an unprecedented ease of use as both the machining centre and Cargo are directly managed by the Maestro active HMI interface.

Software & services

With technological innovation being a core element of the SCM experience, software and services are increasingly the main element of a continuous and shared relationship with the client. Maestro lab is the new cutting-edge CAD/CAM programming software for both office and machine use. Intuitive and dynamic, it allows the user to easily transform an idea into a finished product, thanks to intelligent and technologically advanced programming functions and more than 150 pre-integrated apps; this means that information can be sent from office to factory in record time, thus ensuring a fast user experience.

The contextualised and continuous exchange of information from machine to cloud – made possible due to the IoT Maestro Connect platform – allows SCM to quickly answer customer questions and give specific advice; this supports operators and maintenance workers with specific challenges and needs for autonomy when using, carrying out maintenance, and programming both machine and software.

A specific area created inside the Technology Center will demonstrate how data is transformed into bespoke assistance and advisory services – which are both proactive and predictive in nature – with a view to guaranteeing operational continuity for the client thanks to the most evolved digital technologies and level of service offered by the SCM Service team.

New automated spare parts warehouse

SCM continues to invest in its excellent customer service and during the event, Autostore will be opened – a new automated spare parts warehouse. This innovation has allowed SCM to increase code pick-up speed and increase the number of orders handled within a 24 hour period, which equates to a 26% rise. Along with an energy consumption of under 0.1kWh per robot, this truly confirms the Group’s sustainability focus.

Within this, ergonomics and ease of use also come to the fore, and all machine operators can benefit from the new eye-M control panel, which not only makes work easier but also offers modular programming and higher calculation power.

Other technological innovations – furniture industry

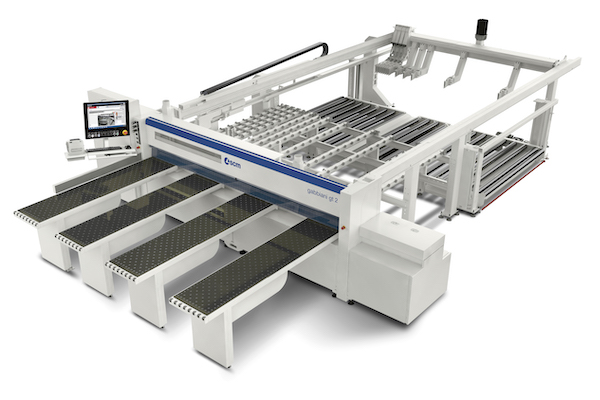

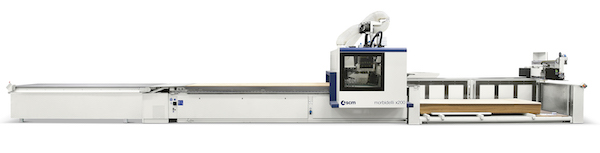

The new SCM Technology Center will see flexible cells integrated with the unmanned AMR shuttles – for beam saws – the gabbiani gt2 with robot for loading and unloading; for edgebanding – stefani cell E with gantry panel return system; for drilling and dowelling – morbidelli cx220, which can be used with either robot only or partially manned. Another highlight will be a beam saw and nesting cell for batch 1 with flexstore hp automatic warehouse and robot for unloading finished pieces, small pieces and waste; the gabbiani p80 panel saw and morbidelli x200 nesting machining centre, which are integrated into the same warehouse.

A particular edgebanding highlight is the new olimpic 500plus, which can achieve even higher productivity levels, by machining edges in solid wood up to 12mm and gluing plastic edging using hot-air technology for an invisible glue line.

For assembly, action e is equipped with a new loading and unloading system, which greatly aids the operator; and action p is a loading and unloading electromechanical clamp machine with a new HMI, that allows work programs, production data and general database information to be both imported and exported.

Surface treatment

The latest in the dmc eurosystem – for sanding and calibrating – will be presented for machining work on both raw and painted panels. These include the new 15in eye-S control panel to manage all sanding functions directly from the touch-screen; the new Maestro active sand HMI for managing tool storage; and a new planetary unit for ensuring a precise finish on any surface.

Also on display will be the new dmc sd 90 functions – a highly customisable solution that’s available in 12 versions, for guaranteeing the best results on solid wood, veneered, lacquered and painted panels.

Visitors will be able to request specific demos at the Surface Lab in Villa Verucchio – Rimini – for the new dmc system with laser engraving unit, for exclusive productions and 3D marking on wood flooring, solid wood elements, MDF panels for veneering, fibre cement and solid surface panels of any length.

In partnership with the Superfici Technology Center, there’ll also be demos for new painting and finishing solutions such as the compact xl sprayer for high capacity productions and a more efficient paint recovery system; the innovative UV LED curing system, which delivers results fully comparable to conventional UV curing, while keeping the advantages of LED.

Excimatt – Superfici’s excimer technology for finishing various products and materials – is capable of providing extra-opaque effects with velvet smoothness without compromising surface strength. The cartesian and articulated robots – for painting window frames and panels – are designed to guarantee production speed and continuity together with a very high level of precision and machining quality.

Windows, doors & solid wood

The Grand Opening will also present an opportunity to discover and explore the newly expanded Rimini factory, including the new system 9 integrated line for windows and door manufacturing along with the celaschi action bilateral tenoning machine.

The SCM line stands out due to its rapid setup changes and the extreme versatility available for managing workpiece lengths; this allows up to 200 complete windows to be produced per shift, even with medium-small batches. In particular, the new celaschi action is able to process two elements of different lengths simultaneously, exploiting the principle of machining with moving motors and stationary workpieces. Another advantage is offered by the four electrospindles, each of which is served by an eight-position tool changer.

Windorflex – the new automatic machining cell for producing complete windows – optimises productivity by ensuring high flexibility and machining quality, and will also be on show at the Rimini plant. In other news, the automatic superset nt automatic throughfeed moulder is now equipped with SCM’s Maestro connect IoT platform, which ensures intelligent and connected production of profiles for windows, doors, stairs, frames and furnishings.

Also new is connexus fj – a tenoning-mortising machine that meets all machining demands for different kinds of solid wood or coated MDF – including complex joints such as mitre door, face frame and French joints on cabinet doors and shutters.

Timber construction

Ample space will also be dedicated to the latest timber construction innovations, which will be presented digitally.These include oikos xl plus – a new CNC machining centre for processing modular panels and structural columns with a maximum cross-section of 1.250 × 610mm – which are used in the construction of multi-storey buildings. The presence of an independent saw blade unit, in addition to a six-axis operating unit, allows through cuts to be performed even on the highest thicknesses.

Also on show will be the oikos xs cnc machining centre, which guarantees maximum performance speed, precision, configurability and reduced footprint when processing glulam or solid wood beams with a maximum cross-section of 450 × 240mm; and lastly, dmc system xl, specifically designed for machining X-lam/CLT walls. This highly modular automatic sanding-calibrating machine is capable of processing CLT panels up to 3,700mm wide × 500mm thick.

Joinery machines

SCM’s most representative joinery machines will also be on display, including stand-alone solutions in addition to integrated ones such as those within the Smart&Human Factory integrated cell. These technologies for beam saw, edgebanding and drilling allow for flexible and customised production from raw material to finished piece of furniture, and enhanced by the integration with MES software.

Other new entries will include ‘blade off’ – SCM’s innovative safety system for circular saws, which, thanks to its smart sensors, prevents accidental contact between user and blade; and startech cn k – a compact 3-axis NC machining centre for any kind of routing, decoration, engraving, signboard production and 3D model prototyping.

For further information and registration, visit https://www.scmgroup.com/en/scmwood/news-events/events/e189590/grand-opening.

- Log in or register to post comments